Does Wool Wax / Lanolin Need Vegetable Oil?

(Short answer: No. Long answer: Also no. But with science.)

Welcome to another post in our Rustproofing, Unfiltered series, where we expose the truths, tricks, and half-baked chemistry of the undercoating world—without the spin.

Today’s topic? A question we hear more than you’d think:

“Can I add vegetable oil to wool wax to thin it out and make it creep better?”

Let’s break it down with a little chemistry, a few facts, and a dash of common sense.

🧪 The Thinking Behind It

Lanolin-based rustproofing products (commonly referred to as wool wax undercoatings) are known for being a little… thick.

And by thick, we mean:

- Harder to spray

- Slower to move

- Sometimes sticky on a cold day

Some folks, including manufacturers of viscous formulas, have suggested a DIY fix:

“Just cut it with vegetable oil.”

Sounds harmless, right? After all, vegetable oil is natural, biodegradable, and hey—it’s in your kitchen.

But what’s good for sautéing asparagus is not good for your vehicle.

❌ Why Adding Vegetable Oil Is a Bad Idea

1. It Reduces Corrosion Resistance

Vegetable oils oxidize rapidly—especially when exposed to heat, oxygen, and salt. This creates sticky residues that trap moisture instead of repelling it.

Reference: ScienceDirect: Oxidative Stability of Vegetable Oils

2. It Fails to Displace Moisture

Wool wax undercoatings are designed to displace water from metal. Lanolin excels at this.

Vegetable oil doesn’t bond to metal or displace water effectively, which limits its protective power.

Reference: NACE International – Understanding Corrosion

3. It Degrades the Product Over Time

Vegetable oil is biodegradable, which invites microbial growth—leading to microbial-induced corrosion (MIC).

Yes, that’s a real thing. And no, it’s not covered under your rust warranty.

Reference: NCBI – Microbial Corrosion in Automotive Systems

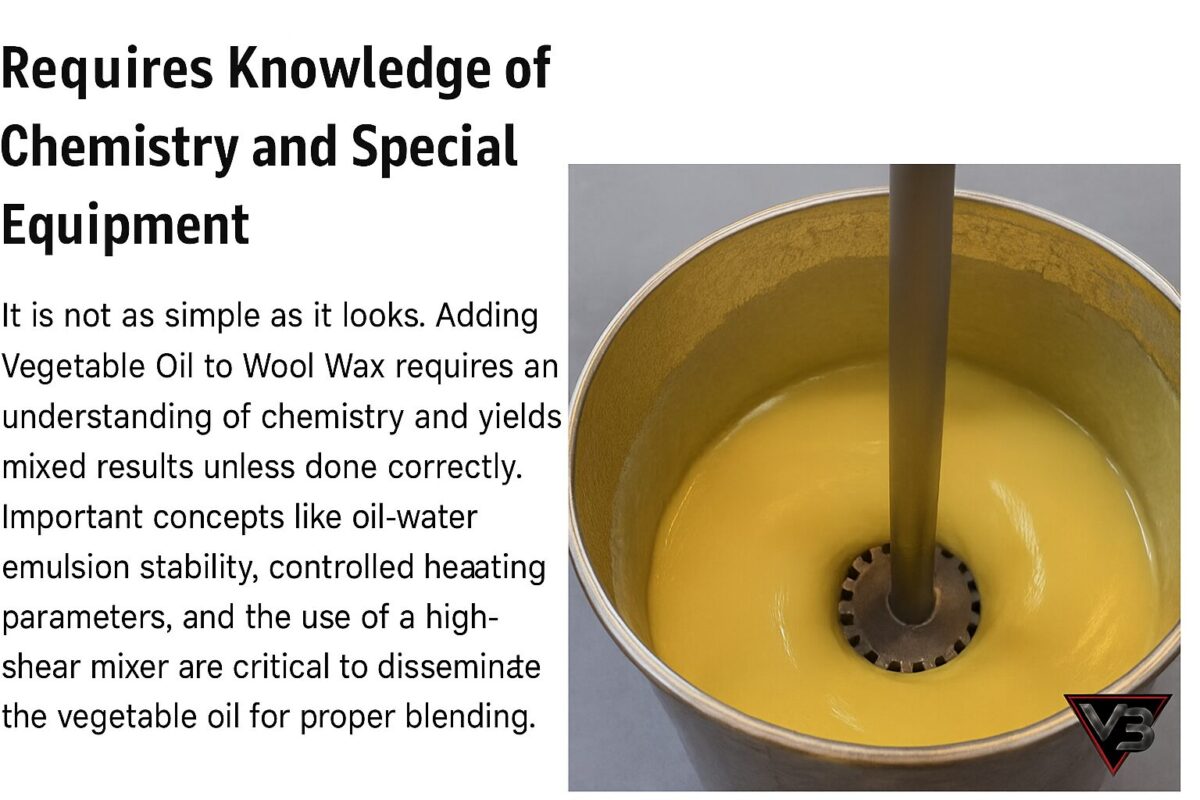

Mixing Isn’t Simple Chemistry—It’s Advanced Formulation

Thinking about thinning your wool wax undercoating with vegetable oil? Think again. You’d actually need:

- High-shear mixing equipment for stable dispersion of immiscible oils – Fluid Handling Pro

- Precise temperature control to avoid phase separation – Wahal Engineers

- Knowledge of emulsifiers and additives to maintain chemical stability – Making Skincare

Without this, your DIY mix may lead to:

- Poor film uniformity

- Inconsistent moisture displacement

- Premature product breakdown

NHOU’s V3 formula is pre-engineered for performance—no mixing, no modifying.

Research Confirms Limited and Situational Efficacy

Plant-based corrosion inhibitors show promise in labs—but are rarely field-ready. ScienceDirect Study

DIY mixing risks:

- Inconsistent film thickness

- Poor moisture displacement

- Premature product failure

This isn’t backyard chemistry—it’s advanced engineering. That’s why NHOU’s V3 formula works straight from the pail.

🛡️ What NHOU Does Differently

At NHOU Protective Coatings, we don’t ask you to fix our formula with cooking oil. NHOU V3 is engineered to perform out of the pail:

- Lanolin for natural corrosion protection

- Moisture-displacing additives

- Refined waxes and oils for creep and durability

- No added vegetable oil. Ever.

We test every batch in-house—and apply it in our own shop. We don’t just sell it. We spray it.

🗣️ What You Can Do

Before your next appointment, ask your applicator:

“Are you cutting the product with vegetable oil?”

If they are—red flag. If it’s NHOU—you’re good.

🔍 Want to Verify This Info?

We built this series to empower you with:

- 🔗 Scientific sources

- ✅ Real-world test insights

- 📚 Dedicated references (like this one)

Informed customers make better decisions.

If you find a better product—use it. Then call us. We’ll make ours better.

💬 Final Word

Adding vegetable oil to rustproofing is like watering down your coffee. It cools it off—but ruins the experience.

Does wool wax need vegetable oil?

No. Not if it’s made right.

At NHOU, we don’t believe in fixes. We believe in formulas that work.

🔗 Related Links

🧠 Stay Tuned

This is just the beginning of our Rustproofing, Unfiltered series. We’re diving into the science behind every can.

Next up: Does Your Rustproofing Product Really Creep Where Rust Starts?

Follow, subscribe, or bookmark—because the best protection starts with the best information.

And one last thing…

If we talk about an ingredient that’s also a brand name—that’s not a jab. It’s just science. We don’t do spin. Just chemistry.

Buy US Direct

Buy US Direct Buy CA Direct

Buy CA Direct Buy EU Direct

Buy EU Direct Buy DE Direct

Buy DE Direct